Industrial friction materials are products used to reduce or eliminate friction between moving surfaces. Friction refers to the force that resists the relative motion of solid surfaces, fluids, or gases in contact with each other. In general terms, there are two types of friction: static and kinetic.

What is Static Friction?

Static friction is a force that resists movement by applying the force in opposition to the motion.

What is Kinetic Friction?

Kinetic frictional force opposes motion between two objects that are moving relative to each other. For example, imagine you are rubbing your hands together quickly and then suddenly stopping. Your hands will keep moving due to kinetic friction until they slow down enough for static friction to overcome kinetic friction, causing your hands to control.

Uses of Industrial Friction Materials

The primary use of industrial friction materials is to reduce the amount of force required to move a load. Friction is a significant factor affecting how much work you need to do on an object before moving.

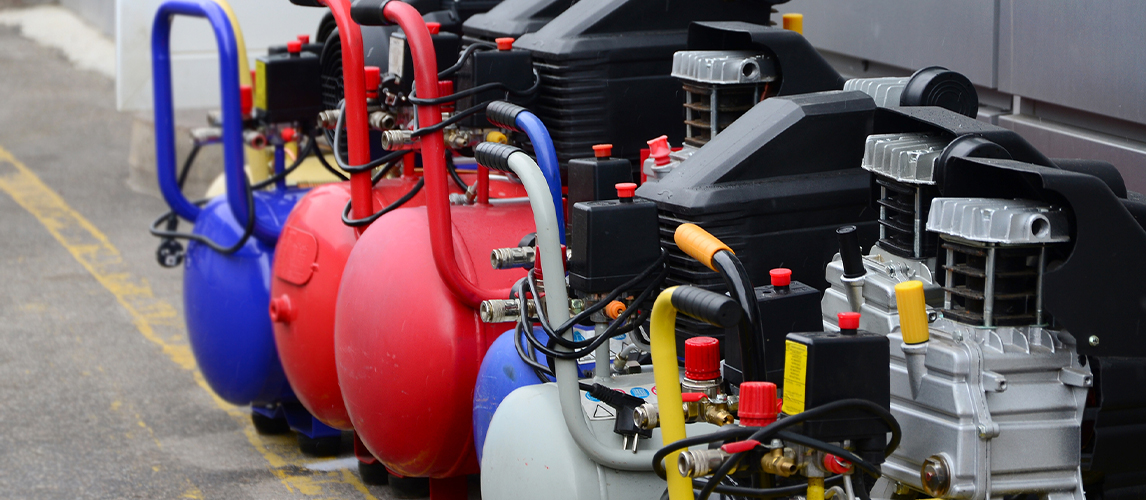

Industrial Friction Material Applications

Applications of industrial friction products include conveyors, chains, bearings, and more.

Industrial friction material applications include:

- Conveyors

Industrial conveyor belts are used to move products or materials from one place to another. Conveyors come in different forms, such as bucket elevators, conveyor belts, and more.

- Industrial chains

They are applicable for large-scale heavy objects such as racking systems, cranes, lifting machinery, and more.

- Rolling bearings

Industrial rolling bearings are applicable in power transmissions such as gears, spindles, and rollers to give the rotational motion for moving objects such as conveyor belts or pulleys.

- Agricultural equipment contact surfaces

Agricultural equipment is subject to heavy wear and tear due to the constant processing of crops. The use of coatings or friction materials can prolong the life of these machines by reducing friction, increasing efficiency, and increasing performance.

- Industrial storage hoppers

Industrial friction products are used in applications, including industrial storage hoppers, to reduce resistance when unloading.

Materials used to make Industrial Friction Materials

There are many different types of materials used to make industrial friction products. They vary in their characteristics and usage:

- Natural Rubber

Natural rubber (NR) is a degradable natural product produced from the sap of plants such as heveabrasiliensis, used for thousands of years by ancient civilizations in everything from clothing to footwear to industrial applications.

- Synthetic Rubbers

Synthetic rubbers are available in different formulations with many other properties, making them suitable for a wide range of industrial applications. They are synthetic compounds created from chemical reactions rather than natural materials. When creating these chemicals, certain characteristics can be modified to create specific types of products with the desired end-use properties.

- Lithium-based greases

Lithium grease is a white lithium complex grease with high detergent and EP performance. It was specifically designed to address the need for oilfield applications where low-temperature fluid returning from downhole tools had higher impurities, acids, and water levels.

Conclusion

Industrial friction materials are used for many different applications, and you can source them from a reliable industrial supplier. These products can increase efficiency, performance and prolong equipment life. However, they all reduce the amount of force needed to move an object that would otherwise be required without industrial materials.