The rotary screw compressor rebuild is a machine that uses a petrol-driven engine or electric motor to power a device that sucks in successive air volumes from the atmosphere, compresses each air volume in a confined place to increase its pressure by making the work much smaller, and then transfers the high-pressure air to a receiver tank. The high-pressure air is drawn off from the receiver tank to power the equipment at hand.

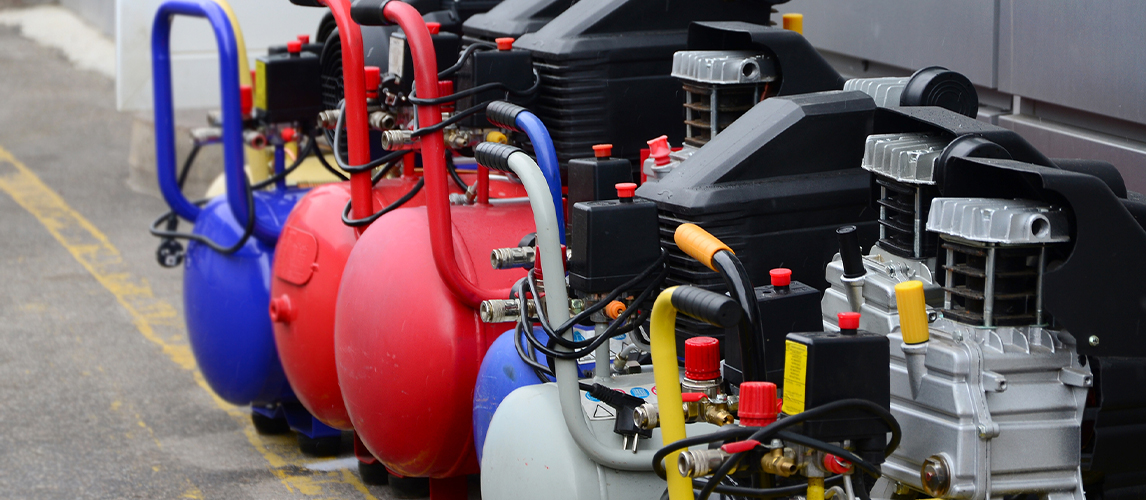

There Are Three Types of Air Compressors:

- Reciprocating compressor Belt Driven- Electric: Uses a piston in a cylinder to squeeze the pressure.

- Rotary screw compressor (Petrol Driven): Uses a rotating spiral screw of gradually diminishing volume to compress the air.

- Centrifugal compressor (Direct – Electric): Uses a rotating impeller to transfer momentum to the air, consequently compressing it.

Air compression started way back in the 1800s, and over the years, invention and improvement of air compressors have continued to happen. There are now different types of air compressors available that use other mechanisms to compress air. The first air compressor was used in mining back in 1861. However, the uses of air compressors are now complete and varied.

If you are looking for air compressors for sale, then you might have come across different capacities, many other models, and different sizes. So which air compressor is right for you?

Common Types of Air Compressors

There are different types of air compressors. However, air compressors can be categorized based on their mode of operation or how they are powered. Air compressors can be classified as either reciprocating piston air compressors or rotary screw air compressors using the function.

Reciprocating piston air compressors

These air compressors are also called piston air compressors. They use a machine with a lot of pistons, crankshafts, valves, and many other parts. They are used in many small businesses because they are inexpensive to purchase upfront. These air compressors are suitable where very high pressures are required. The small ones are air-cooled, but the large machines use water cooling to avoid overheating and maintain efficiency.

Rotary Screw Air Compressors

These rotary screw compressors rebuild have much less movement of parts involved. Only two rotating screws might contact each other during operation and without friction, which reduces wear and tear. The rotary screw air compressors operate continuously, unlike the reciprocating piston air compressors used intermittently to avoid overheating. These types of air compressors cost more upfront than the reciprocating piston air compressors. These air compressors are usually air-cooled and come in compact designs.

Petrol and electric air compressors

Air compressors may also be categorized as petrol-driven or electric based on how they are powered. Petrol driven ones are more versatile because they can operate in areas without electricity or when there is no power.

Uses of Air Compressors

Air compressors may also be grouped into three broad categories based on where they are used. These are; consumer-grade, professional-grade, and industrial grade. The consumer-grade air compressors are ideal for use at home. They are used for functions such as inflating tires and powering small tools like staplers. Professional-grade air compressors are used in small businesses and with DIY enthusiasts that have more powerful tools. They provide more power and can be used to control several significant devices at once.

Industrial grade air compressors

are giant workhorses that provide reliable power for an industry or oil rig. They are used for various purposes, including; moving conveyor belts, spray coating, packaging products, cooling and freezing, cutting and welding, operating machinery, and so much more.